Contribute to the transition to a carbon-free society by reducing automotive, manufacturing, and energy plant construction CO2 emissions through the use of clean energy and innovative technologies

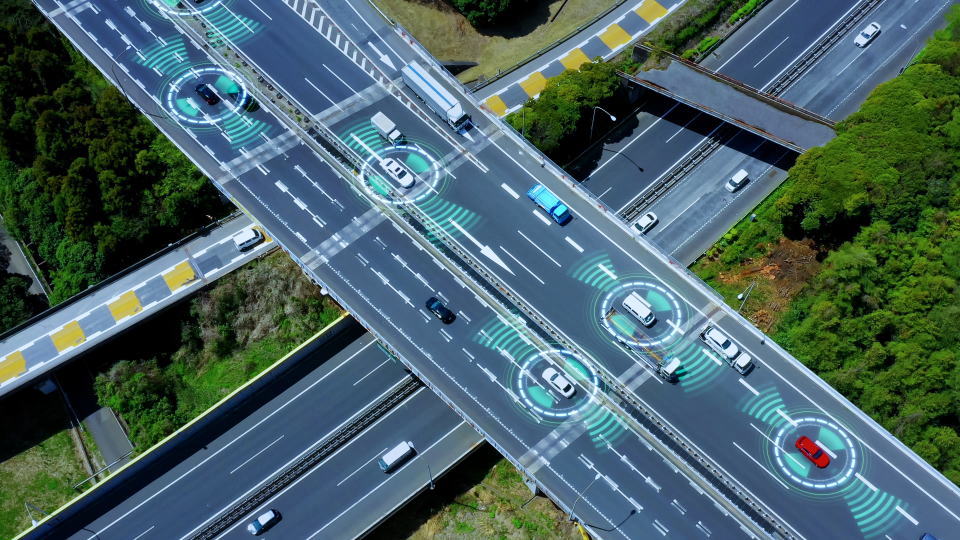

Climate change is a major issue that affects all life on earth. To tackle this issue, the Toyota Tsusho Group is actively increasing sales of next-generation eco-cars (HEVs, PHEVs, BEVs and FCEVs), developing infrastructure such as hydrogen stations, reducing vehicle weights by using alternate materials, and securing lithium resources that support increased production of the automobile batteries essential for eco-cars. We are also using the knowledge we have accrued through our experience with renewable energy business, such as wind and solar power generation, together with various innovative technologies to contribute to the realization of a sustainable carbon neutral society by reducing automobile CO2 emissions and CO2 emissions throughout product lifecycles, including in the logistics business, and contributing to the elimination of CO2 emissions from plants.

Proportion of renewable energy in the company's total electric power generation capacity

- *Renewable energy includes wind power (including offshore windpower), solar power, geothermal power, hydroelectric power, and wood biomass power.