Refrigerated Vaccine Transport Vehicles Connecting the Last Mile to Protect the Lives of Children in Developing Countries

August 19, 2024

The Reality of Developing Countries Where Many Children Die Before Reaching the Age of Five

Global health is a major issue for international society regarding health and sanitation on a global scale. As one of the 17 SDGs is “Good health and well-being,” it is imperative that not only governments but also international organizations, public-private partnerships, and other industry, government, and academia work together to contribute to the goal of a better society in which everyone can receive proper health care services such as prevention and treatment.

Every year, more than five million children lose their lives before reaching the age of five. Approximately 80% of these deaths occur in developing countries in the Global South, such as in Sub-Saharan Africa and South Asia, where there are large health disparities. The under-five mortality rate in Sub-Saharan Africa is more than ten times than in developed countries in Europe and North America.*1 The most common causes of death are pneumonia, diarrhea, and malaria, and vaccines are one of the most effective methods to prevent infectious diseases like malaria and measles. *2 If vaccines are delivered to children and they have an environment where immunization is accessible, many lives can be saved.

Bottlenecks in Vaccine Transport – The Last Mile

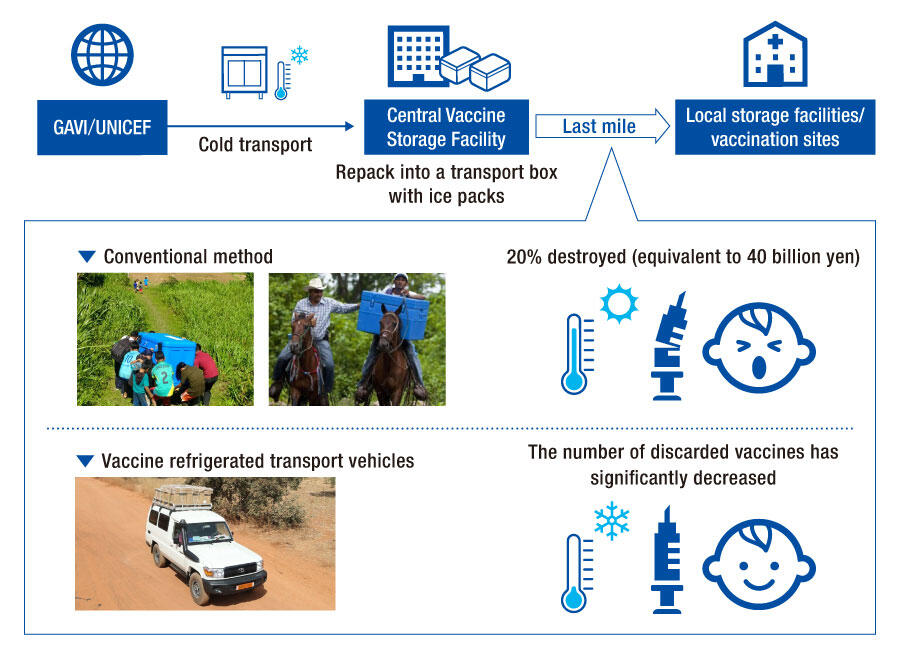

Many vaccines are supplied to developing countries, including African countries, by Gavi, the Vaccine Alliance*3 (“Gavi”) , a global alliance that aims to promote vaccines and immunization, and by international organizations such as UNICEF.

In order for children to receive immunization, vaccines must be properly transported to the final destination. Vaccines are heat sensitive and become unusable once they exceed a certain temperature. For example, neonatal vaccines must be stored at 2~8℃. Therefore, cold chain transport is essential for vaccines.

Vaccines supplied by Gavi and other organizations are transported in refrigerators to local health centers. The vaccines are then generally packed in transport boxes with ice packs and delivered to hospitals.

However, many developing countries have underdeveloped transportation infrastructure and limited means of transport. Although the vaccines are temperature-controlled and delivered to health centers in urban areas, they must be transported from the health centers to hospitals by ordinary cars or motorcycles without refrigeration equipment, or in some cases, they must be carried by people for hours in temperatures that exceed the optimum temperature for vaccines.

Due to these circumstances, approximately 20% of the entire vaccine supply (equivalent to 40 billion yen) has been wasted, which is one of the reasons 1.5 million children have lost their lives every year to vaccine-preventable infectious diseases.

What We Could Do as a Trading Company

Creating New Value by Connecting and Combining

The last mile of the vaccine cold chain has long been considered an issue. It has also been recognized that there are clear needs and social significance for its solution, and that it could be solved by developing and introducing the “refrigerated vaccine transport vehicle,” a vehicle suitable for refrigerated transportation.

However, no company took the initiative to develop refrigerated vaccine transport vehicles. This is because the scale and feasibility of the market was unknown. In addition, the World Health Organization (WHO) requires that the Performance, Quality and Safety (PQS; more details below) prequalification for quality of medical devices and equipment be obtained to provide refrigerated vaccine transport vehicles, but this was considered an extremely high obstacle to overcome.

Under these circumstances, one of our company’s employees voiced their desire to change the current situation somehow.

The idea was to connect medical equipment manufacturers and vehicle manufacturers to create a refrigerated vaccine transport vehicle. We proposed the idea to B Medical Systems, a Luxembourg-based medical refrigerator manufacturer with whom we have a long-standing relationship, and Toyota Motor Corporation, and received support from both companies.

A Toyota Land Cruiser 78 was used as the vehicle for the refrigerated vaccine transport vehicle. This vehicle is suitable for off-road driving and can be driven on roads in developing countries. In addition, the vaccine refrigerator produced by B Medical Systems has a storage capacity of 396 liters (or 400 pediatric vaccine packages). The refrigerator can operate for approximately 16 hours without power and can be recharged from the vehicle while driving and from an external power source while parked.

There were many difficulties in the development of the vehicle, including the installation of the refrigerator in the vehicle, temperature control of the refrigerator itself, and power supply. However, our strong desire to deliver vaccines at any cost finally led us to the realization of the refrigerated vaccine transport vehicle.

Toyota Tsusho is not in the business of manufacturing vehicles or refrigerators, but by “connecting” different industries, which is one of the strengths of a trading company, we were able to create something that had never existed before.

First Refrigerated Vaccine Transport Vehicle in the World to Obtain International Prequalification and Promote Supply

In March 2021, Toyota Tsusho, along with B Medical Systems and Toyota Motors Corporation, obtained the PQS prequalification for quality of medical devices and equipment as set by the WHO for refrigerated vaccine transport vehicles. PQS stands for Performance, Quality and Safety and is a system for the qualification of medical devices and equipment by WHO that was established to promote the development of medical devices and equipment applicable for the United Nations’ procurement as well as to set quality standards. Medical devices and equipment which have obtained PQS prequalification also meet the equipment selection standards of agencies related to the United Nations, NGOs, and other charity organizations. Also, it is easier to provide supply to developing countries without their own qualification system for medical devices and equipment by using PQS as the qualification standard.

It was an unprecedented and difficult challenge, but as a result of paving the way step by step, the world’s first refrigerated vaccine transport vehicles which have obtained PQS prequalification can now be supplied.

Upon receiving this prequalification, we delivered ten refrigerated vaccine transport vehicles to the Ministry of Health of the Republic of Ghana in November 2021. This was the first delivery of refrigerated vaccine transport vehicles.

In addition to transporting pediatric vaccines, the refrigerated vaccine transport vehicles have also proven effective in supplying COVID-19 vaccines to developing countries. Gavi, WHO, and other organizations have established a framework to supply vaccines to 92 developing countries. In May 2021, in support of this initiative, we donated 100 million yen and provided five refrigerated vaccine transport vehicles to Gavi COVID-19 Vaccines Advance Market Commitment ("Gavi COVAX AMC")*4, which supplies COVID-19 vaccines to developing countries.

In July 2022, in collaboration with Gavi, we began field driving tests of refrigerated vaccine transport vehicles for approximately one year. This joint test is intended to verify the contribution of refrigerated vaccine transport vehicles to Gavi’s initiative to eliminate “Zero-dose Children” (children who lack the first dose of diphtheria-tetanus-pertussis containing vaccine (DTP1)).

The results of the joint trial, completed in June 2023, have confirmed the success of the project in reducing vaccine waste and operating costs and improving the efficiency of transport operations. As a result, Gavi highly evaluated refrigerated vaccine transport vehicles as a revolutionary solution for last-mile transportation in the vaccine cold chain.

- *4Gavi COVAX AMC is a framework for supplying COVID-19 vaccines to developing countries.

Vaccines for Children in More Regions

Since the first delivery of vehicles in 2021, refrigerated vaccine transport vehicles have been steadily spreading. In June 2023, 48 vehicles were ordered from Niger utilizing funds for the development of the vaccine cold chain provided by the World Bank. Currently, more than 170 refrigerated vaccine transport vehicles are on the road in more than 20 developing countries to save lives.

Refrigerated vaccine transport vehicles were born from the passion of one trading company employee. The supply of these vehicles in Africa has just begun. There are many children in the region waiting for improved last-mile transportation. In addition, there are many areas outside of Africa where vaccines cannot be delivered due to road conditions or transport methods.

After the COVID-19 pandemic, awareness of global health is increasing further worldwide. Toyota Tsusho aims to contribute toward global health, which will help realize a healthy society where we “leave no one behind,” by promoting the use of refrigerated vaccine transport vehicles.

We will continue striving to solve social issues for the purpose of “passing on a better global environment to the children of the future.”

Past Initiatives for Refrigerated Vaccine Transport Vehicles (Press Releases/Notices)

- First Refrigerated Vehicle for Vaccine in the World to Obtain WHO's Performance, Quality and Safety Prequalification

- Establishing methods for refrigerated vaccine transportation and contributing toward improving the rate of vaccine use in developing countries - - Toyota Tsusho Signs Basic Agreement with Gavi, the Vaccine Alliance to Supply COVID-19 Vaccines to Developing Countries (One Year of Field Driving Tests)

- Toyota Tsusho Delivers First Refrigerated Vaccine Transport Vehicles to the Ghana Ministry of Health

- Safely and securely transporting vaccines, including COVID19 - - Toyota Tsusho Completes Joint Test with Gavi, the Vaccine Alliance on Refrigerated Vaccine Transport Vehicles

- Recognized for results including reduced vaccine damage, reduced operating costs, and more efficient transport operations - (in Japanese)

Gavi Project Video (English Subtitles)

Mobility Planning Department

We had long been aware of the issues facing refrigerated vaccine transport and the white space market that exists there through our many years of involvement in vaccine and medical ODA. On the other hand, we had no idea what kind of market and on what scale it would be. In addition, we needed the PQS prequalification from the WHO to realize the project, so it was obvious that the bar was high. However, with the idea that “someone has to take the lead,” we took on the challenge of creating a new business by connecting companies to fulfill our unique role as a trading company, and we became the first company to obtain the WHO prequalification in the vaccine transport sector. We will continue striving to solve issues in developing countries including those in Africa.

Mobility Planning Department

One of the seven priority domains in our growth strategy is “Economy of Life,” and the Mobility Division, to which I belong, is tackling global health, which is a new area for us. In tackling global health, we are required to be professionals not only in the field of vehicle products, but also in “healthcare.” Every time I go to developing countries in Africa and other regions and see the issues facing medical services, I am aware of the social significance and responsibility of being involved. Starting with our first product, the refrigerated vaccine transport vehicle, we will continue working on initiatives to save lives through our unique mobility business in the domain of global health.

- Domestic

- Overseas

- NEW