Pollution Prevention

Policy

The Toyota Tsusho Group complies with the Air Pollution Control Act, Water Pollution Control Act, and other relevant laws and regulations, takes action to reduce the release of pollutants, and actively works to maintain and preserve natural environments.

Pollution Risk Countermeasures

1.Toyota Tsusho conducts pollution abatement that exceeds the requirements of laws and regulations

At the Toyota Tsusho Group, We regularly check laws and regulations and set our own targets every year, aiming to keep within 80 percent of the standards set out by environmental laws and regulations. We manage these voluntary standards on a daily basis, and check compliance through internal audits.

In fiscal 2024, the Group has not been subjected to any fines or penalties and has not committed any violations or non-conformance with environment-related laws and regulations, and consequently, no associated costs were incurred.

- <Objective>

- In addition, not only do we comply with laws and regulations, we take action with the aim of preventing pollution. For example, each year we work to achieve a target of zero oil leaks from commercial vehicles, and in fiscal 2023, there were no leaks. We obtain information on oil leaks from business partners and share that information globally on a monthly basis in an effort to educate the relevant parties.

2.Chemical management

The safe handling of chemical substances is an important foundation of our chemicals business. With the aim of protecting human health and safety, as well as the global environment—including water, soil, air, and ecosystems of flora and fauna—we are promoting centralized management of chemical-related information and have established a management system to ensure appropriate compliance with relevant laws and regulations concerning the chemical products we handle.

- 1System

The Toyota Tsusho Group has established company-wide policies and goals related to sustainability, including pollution prevention, as well as a system to implement them. The status of management is reported to the Specified Import & Export Control Committee*, and significant matters are reported to the Board of Directors as necessary.

We also engage external consulting firms with advanced expertise in chemical management to provide comprehensive advice on our management systems and individual consultations on applicable laws and regulations for each product.

In the event of an emergency, the responsible sales department and the Administrative Unit coordinate to determine how to respond. In line with the Toyota Tsusho Group’s communication protocol for emergencies, “Bad News First & Fast,” we report promptly to both internal and external stakeholders and respond appropriately based on the circumstances of the incident.- *The Specified Import & Export Control Committee is a company-wide body established for the purpose of security assurance and export control.

- 2Specific Initiatives

In our chemicals business, we verify the laws and regulations applicable to all chemical substances based on their chemical composition and standard performance. We compile lists of the CAS Registry Numbers and content ratios for the chemical substances contained in each product, organized by safety data sheet (SDS), and centrally manage this data through our chemical management system. By registering substances on an individual component basis, we are able to respond appropriately to regulatory requirements of each country related to specific components. In addition, we participate in relevant industry organizations to stay informed about the latest developments in chemical substance regulations. To ensure the proper communication of hazard and toxicity information about chemical substances throughout the supply chain, we provide an SDS for each product, thereby delivering accurate information to stakeholders.

- 3Compliance with Environmental Laws and Regulations

We comply with a wide range of specific laws and regulations related to environmental management systems, including the Act on the Regulation of Manufacture and Evaluation of Chemical Substances (ARME), the Industrial Safety and Health Act (ISHA), the Act on the Assessment of Releases of Specified Chemical Substances in the Environment and the Promotion of Management Improvement, the Poisonous and Deleterious Substances Control Act, the Fire Service Act, and the High Pressure Gas Safety Act.

For example, we ensure accurate reporting and registration in accordance with laws, such as annual volume reports, new chemical substance registrations, and small-quantity new chemical notifications under the ARME, and small-quantity new notifications under the ISHA.The main laws and regulations we comply with by region and country are as follows.

Region/Country Applicable Laws and Regulations Japan ARME, ISHA USA TSCA, HCS (OSHA) EU Countries REACH, CLP China Measures for the Environmental Management of New Chemical Substances, Regulations on the Safe Management of Hazardous Chemicals South Korea Act on Registration, Evaluation, etc. of Chemicals (K-REACH), Occupational Safety and Health Act Taiwan Toxic and Concerned Chemical Substances Control Act, Occupational Safety and Health Act ASEAN Countries Under development and implementation in respective countries - 4Handling of Chemical Substances with Potential Environmental Risks

To comply with various laws and regulations, industry standards, and customer requirements, we employ chemical management specialists to identify hazardous substances contained in our products and raw materials. When a chemical substance is deemed to pose a potential environmental risk, we proactively work to reduce or phase out its use and emissions, and replace it with an alternative. Through these efforts, we strive to minimize the environmental impact of our products. Furthermore, we prohibit the intentional addition of hazardous substances.

- 5Education

We regularly provide e-learning programs and training sessions on chemical management and environmental laws and regulations for all officers and employees in our chemicals business. The training sessions are tailored to their respective roles and levels of expertise.

In particular, we offer training for overseas assignees on key laws and regulations and regulatory requirements specific to each country, helping to enhance their understanding of local legal frameworks.

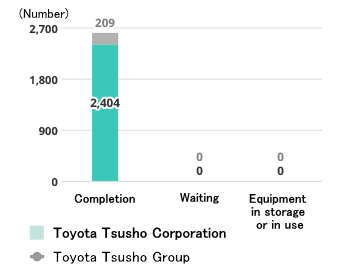

3.Promoting Toyota Tsusho Group integrated disposal of equipment containing PCB

The Toyota Tsusho Group recognizes that equipment containing PCB (equipment in storage or in use) is a major environmental risk. For that reason, since 2015 we are promoting integrated waste disposal as a way to dispose of waste as early as possible and reduce environmental pollution risk.Since fiscal 2022, the disposal completion rate for equipment containing PCB has been 100%.

Performance Data

| 2020 | 2021 | 2022 | 2023 | 2024 | FY2024 | |

|---|---|---|---|---|---|---|

| Water quality (Total BOD) |

1.4 | 1.3 | 0.9 | 0.7 | 0.4 | 0.2 |

For domestic water quality data, BOD is calculated only for waste water after proper treatment (discharges into rivers)

Costs of pollution, waste, and raw material challenges

- Pollution and waste-related costs (shadow costs): 0 yen

Traditionally, the estimated cost for processing equipment containing PCB was listed as a possible future cost (shadow cost). Since equipment containing PCB has now been completely disposed of, this cost is now listed as 0.

- Investment in R&D related to technologies that promote the cyclical use of resources through the recycling and refurbishment of CO₂ generated during waste disposal: 8,456,650 yen