Occupational Health and Safety Initiatives

- The Toyota Tsusho Group's Policies on Safety and Health

- Safety and health management promotion framework

- Health and safety committees

- Safety and Health Promotion Activities at Toyota Tsusho Group and Suppliers

- Number of industrial accidents and industrial accident rates

- Third party certification

- Due diligence in occupational safety and health

- Safety and health training

- Toyota Tsusho Group Employee Health Management Declaration

- Toyota Tsusho Health Management Initiatives

- Health management strategy

- Health and productivity management promotion framework

- Results of health and productivity management initiatives

- Health promotion measures

The Toyota Tsusho Group's Policies on Safety and Health

The Toyota Tsusho Group has set "Begin everything we do with ensuring safety and compliance, and continue to be an organization trusted by society" as one of its key Materialities. We conduct activities based on "Toyota Tsusho Group's Policies on Safety and Health" with the understanding that ensuring the occupational safety and health of not only Group employees but also contract employees, business partners, investors, and other related parties is of the utmost importance. We require that any incidents such as labor accidents or occupational hazards be reported to the designated contact point in accordance with our company-wide emergency reporting system, "Bad News First & Fast." Additionally, if deficiencies in the occupational health, safety, and environmental conditions affect the activities of internal or external stakeholders, we will encourage improvements based on this policy to the relevant parties.

Philosophy

Toyota Tsusho group recognizes that safety and health of group companies' Tsusho group will bring safety and health activity to effect to maintain safe and comfortable work environment.

The Toyota Tsusho Group's Policies on Safety and Health

- 1Toyota Tsusho group top management recognizes that good communication between top management and employees is crucial for safety and health management, and the top management will respect such intercommunication with employees.

- 2Toyota Tsusho group observes the laws of safety and health, guidelines of work operation inside the premises of customers, and Toyota Tsusho group will establish necessary internal rules and regulations to improve the level of safety and health management.

- 3Toyota Tsusho group utilizes the occupational safety and health management system, and Toyota Tsusho group will make efforts to improve and maintain such system to aim at continuously higher level of safety and health.

- 4To promote group companies' total safety and health activities, Toyota Tsusho group organizes proper organization system and will make clear for locus of responsibilities.

- 5To promote comfortable and healthy work environment, Toyota Tsusho group will execute necessary and sufficient education and training for all employees to secure safety and health.

May 20, 2025

President & CEO Toshimitsu Imai

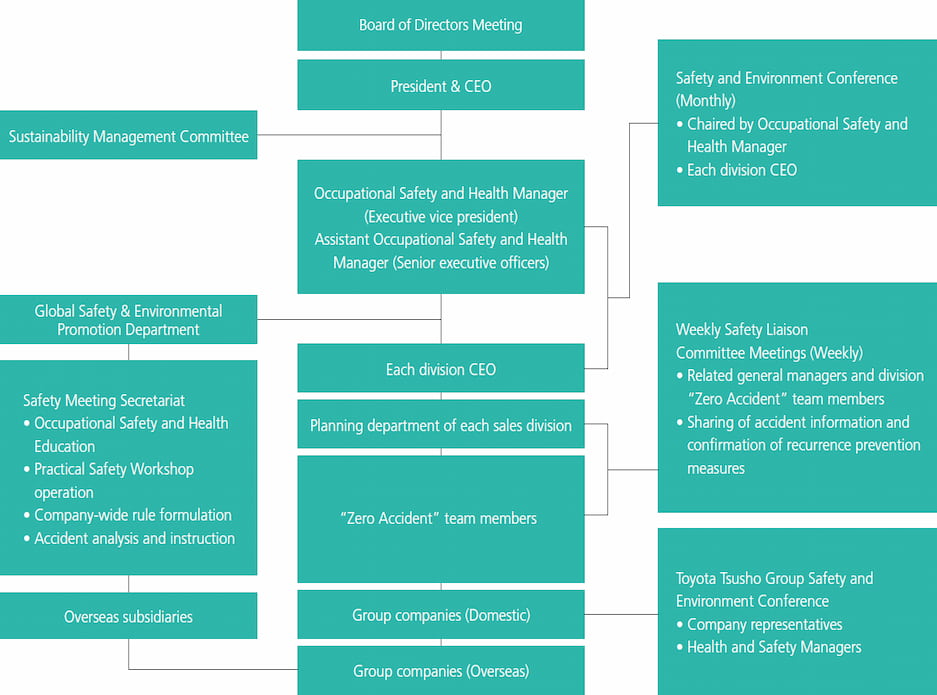

Safety and health management promotion framework

Health and safety committees

We strive to share safety information and raise safety consciousness, with the Weekly Safety Meeting and Global Safety & Environmental Committee at the core of our efforts.

Toyota Tsusho Corporation holds Weekly Safety Meetings attended by safety-related personnel, primarily members of "zero accident" teams in each division.

The company-wide Global Safety & Environmental Committee meets monthly to share information and improve safety awareness among top executives. It is chaired by the Executive Vice President, with divisional executives attending (Division CEO and directors in charge of "zero accident" promotion).

Under the supervision of the Board of Directors, the Toyota Tsusho Health and Safety Committee is chaired by the Chief Human Resources Officer (CHRO), who is responsible for health and safety. The committee meets monthly to discuss employee health and safety environments; it also reports to the Board of Directors on health and safety risks, depending on their severity. The Health and Safety Committee is also attended by a labor union officer, who acts as an employee representative. Together, the committee members discuss how to promote employee health, and how to develop environments in which it is easy to work.

Safety and Health Promotion Activities at Toyota Tsusho Group and Suppliers

Toyota Tsusho established the Safety Management Office in 1985 and the Environment & Safety Management Department in 2001 After the name change of the Safety Promotion Department; even after these were combined into the present-day Safety and Global Environmental Promotion Department in 2010, the company has striven to instill a culture of safety and eliminate and prevent accidents. Via plant safety diagnoses, occupational health and safety management systems, risk assessments, and other initiatives, we are promoting safety management activities at Group companies both in Japan and overseas. We are also focused on expanding the "Toyota Tsusho Global Safety Standard" as a common set of health and safety rules worldwide. Risk assessments are conducted as needed, such as when new tasks arise, when work processes change, for themes aimed at preventing similar accidents, and when introducing new equipment.

In the Occupational Safety and Health Management System (OSHMS), we have revised the content to comply with "ISO45001" from FY2022.

Top management and the head of each sales division personally visit business sites in Japan and overseas to conduct "factory inspections" and "construction safety inspections. In addition, we are striving to improve the level of safety and health management by checking the management system, the activities of the Safety and Health Committee, and the progress of the annual activity plan, conducting "risk assessments" to prevent accidents, and implementing a PDCA cycle to identify issues and implement countermeasures.

Of 383 companies subject to health and safety management, 15 or about 4% have received certification under OHSAS 18001 and ISO45001, international standards for occupational health and safety management.

In Japan, we have established the Toyota Tsusho Group Global Safety & Environmental Committee, to promote occupational safety and health activities at Toyota Tsusho and Group companies in Japan. The Committee is held every August and is chaired by the Executive Vice President, with representative directors of Group companies in Japan attending, and in the August 2024, a total of 299 people from 71 companies participated.

Also, top-level management and the leaders of business divisions personally visit business sites in Japan and overseas to conduct plant inspections and construction safety inspections based on the Safety and Health Management System (OSHMS). We also check the management structure, the status of Safety and Health Committee activities, and the annual activity plan's implementation status. Furthermore, we perform risk assessments in an effort to prevent accidents from occurring. We strive to improve our level of safety and health management by implementing the PDCA cycle to identify issues and implement countermeasures.

Overseas group companies also share the "Anzen First" ("Safety First") philosophy while promoting safety and health initiatives in accordance with local laws and regulations. In addition, we have been holding Global Safety Meetings since fiscal year 2012 with the aim of establishing a globally shared safety culture. The 13th meeting, held in fiscal year 2024 in Thailand in a hybrid format combining in-person and Zoom participation, brought together about 100 participants from 22 countries. Active discussions were held on themes such as the "2030 Safety Vision," "disaster analysis for this fiscal year," "OSHMS," "fire and explosion prevention activities," and "risk assessment." In addition, 11 local participants from France, Brazil, India, Singapore, the Philippines, and Malaysia visited three companies in Thailand to learn through on-site observation.

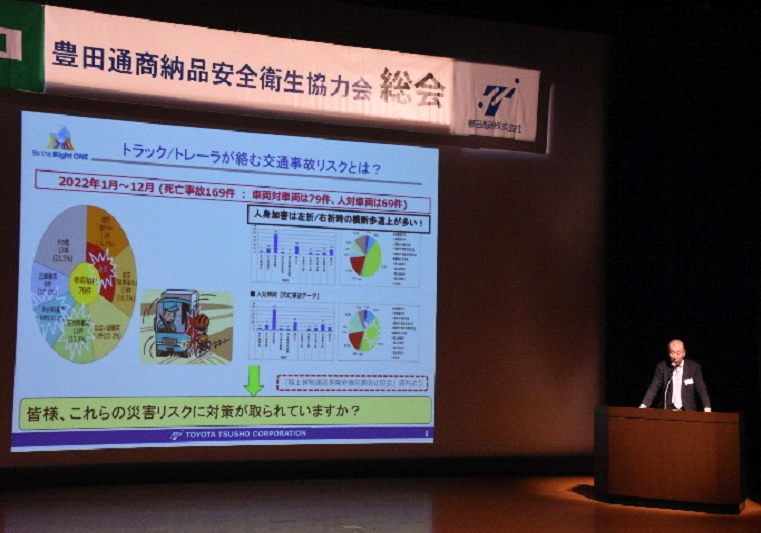

For suppliers, Toyota Tsusho Construction: Safety and Health Cooperation Council for equipment construction and the Toyota Tsusho Delivery Safety and Health Cooperation Council for transportation and delivery promote zero accident and zero occupational injury as well as improved safety and health management at each of our partner companies. The two councils have a combined membership of more than 600 companies, and strive to raise safety awareness through general meetings, safety conferences, and workshops.

Specifically, we support the safety and health activities of member companies by providing various types of safety and health education, such as training for persons in charge of operations, driver training sessions, and forklift training sessions, as well as holding lectures on safety and health. In fiscal year 2024, the training for persons in charge of operations (instructor training) was attended by 93 participants from 51 companies, and forklift training sessions were conducted four times with a total of 23 participants.

In addition, we disclose the In-house Safety Standards for Contractors to subcontractors involved in contracted construction work, require training for contractor workers and compliance with safety rules, and, together with the implementation of safety patrols, strive to ensure a safe working environment for the contractors as well.

We have distributed self-inspection sheets for preventing fires and explosions to 385 companies in Japan and overseas based on the "Fire and Explosion Prevention Policy" formulated by top management. The sheets are used to identify issues and prevent fires and explosions at each company.

Number of industrial accidents and industrial accident rates

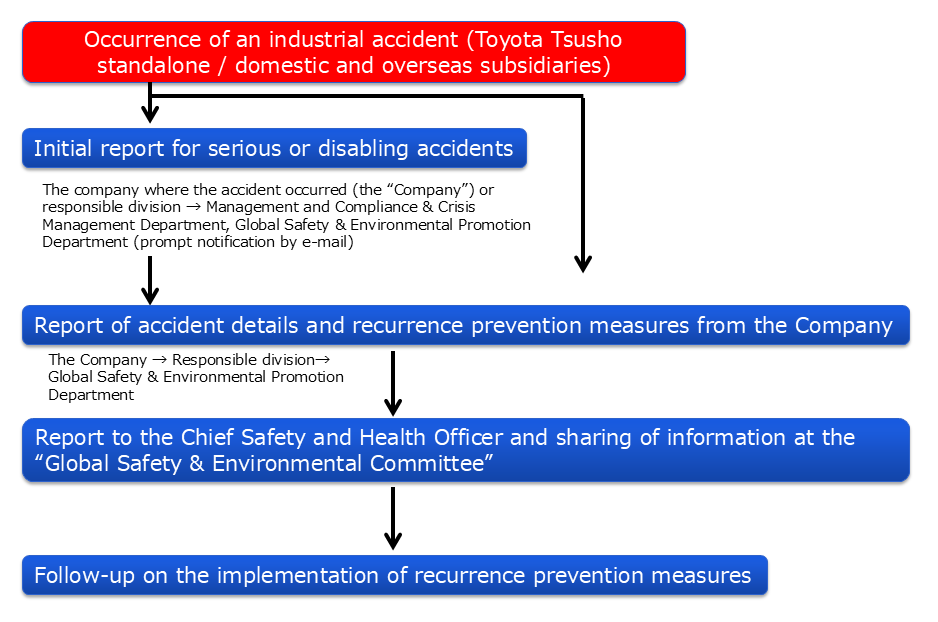

Within the Toyota Tsusho Group, we have established the Emergency Response Guidelines (notifications) regarding communication systems and response policies in the event of an emergency. We also work together with the Compliance & Crisis Management Department and relevant divisions to respond in a timely and appropriate manner

In addition, industrial accidents that occur within the Group are reported without delay through the accident reporting system (ASIST*) in accordance with the Toyota Tsusho Group Industrial Accident Reporting Standards. Root-cause analysis and recurrence prevention measures are disseminated across all departments and utilized to help prevent similar accidents.

- *ASIST: An internal Toyota Tsusho Group system for reporting industrial accidents, disaster countermeasures, and sharing related information

Based on the idea that "the results of our daily safety activities lead to zero accidents," we incorporate specific activities based on an analysis of the details of accidents in the previous year and set annual targets to reduce the number of accidents and illnesses.

We monitor the occurrence of industrial accidents with the targets of zero fatal accidents, zero disability accidents, and zero lost-time accidents. In fiscal year 2024 (April 2024-March 2025), there were zero fatal accidents, three disability accidents, and 64 lost-time accidents. The three disability accidents that occurred overseas were caused by entrapment, entanglement, and heavy objects. In response, we are striving to prevent recurrence by rechecking procedures for responding to equipment abnormalities, reviewing work procedures, and thoroughly disseminating the lessons learned from these accidents globally to the Toyota Tsusho Group’s front-line workplaces.

| Target | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |

|---|---|---|---|---|---|

| Actual Result | Actual Result | Actual Result | Actual Result | ||

| No. of industrial accidents (resulting in lost work time) |

0 | 0 | 0 | 0 | 0 |

| Regular employees | 0 | 0 | 0 | 0 | 0 |

| contractor | 0 | 0 | 0 | 0 | 0 |

| No. of fatalities | 0 | 0 | 0 | 0 | 0 |

| Regular employees | 0 | 0 | 0 | 0 | 0 |

| contractor | 0 | 0 | 0 | 0 | 0 |

| Lost time injuery frequant rates | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

- *Regular employees: Full-time employees

Contract employees: Fixed-term, part-time, temporary, and dispatched employees

| Target | FY 2021 | FY 2022 | FY 2023 | FY 2024 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Actual Result | Actual Result | Actual Result | Actual Result | ||||||||||

| JPN | FOR | TOTAL | JPN | FOR | TOTAL | JPN | FOR | TOTAL | JPN | FOR | TOTAL | ||

| No. of industrial accidents (resulting in lost work time) |

0 | 9 | 72 | 81 | 19 | 88 | 107 | 25 | 65 | 90 | 12 | 55 | 67 |

| Regular employees | 0 | 7 | 67 | 74 | 8 | 86 | 94 | 10 | 62 | 72 | 7 | 50 | 57 |

| contractor | 0 | 2 | 5 | 7 | 11 | 2 | 13 | 15 | 3 | 18 | 5 | 5 | 10 |

| No. of fatalities | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Regular employees | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| contractor | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Lost time injuery frequant rates | 0.00 | 0.35 | 0.72 | 0.61 | 0.60 | 0.73 | 0.70 | 0.77 | 0.50 | 0.55 | 0.36 | 0.42 | 0.41 |

No lost-time accidents for Toyota Tsusho on a non-consolidated basis

- *Lost-time accidents are counted as one day or more of absence.

- *Regular employees: Full-time employees

Contract employees: Fixed-term, part-time, temporary, and dispatched employees

Scope of aggregation: Toyota Tsusho and 385 major consolidated subsidiaries in Japan and overseas, including the Africa Division - *2024 rate of lost time injury frequency rates (Ref. Survey on Industrial Accidents in 2024, the Ministry of Health, Labour and Welfare)

Nation-wide average: 2.10%

Industry average (wholesale and retail industry with 100 employees or more): 2.60%

Third party certification

Third-party certification has been obtained from Lloyd's Register Quality Assurance (LRQA) for a portion of the performance data above.

- LRQA Independent Assurance Statement (JP:Toyota Tsusho Corporation)[PDF:665KB]

- LRQA Independent Assurance Statement (JP:Toyota Tsusho Group)[PDF:673KB]

- LRQA Independent Assurance Statement (EN:Toyota Tsusho Corporation)[PDF:206KB]

- LRQA Independent Assurance Statement (EN:Toyota Tsusho Group)[PDF:591KB]

Due diligence in occupational safety and health

At our investment businesses, we conduct occupational health and safety inspections at the planning stage of construction projects.

With regard to investment projects that involve construction of which the contribution rate is 50% or more, the occupational health and safety standards for risk assessment of new and existing business are expressly stated, the existence of a safety management system is confirmed by conducting audits throughout the construction implementation cycle starting from the planning stage, and measures are taken to reduce occupational health and safety risks.

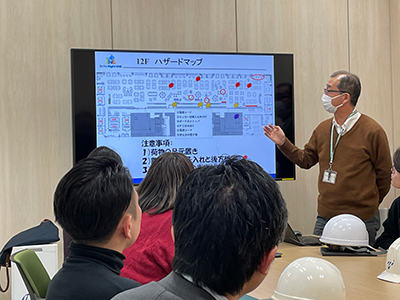

The Safety Management Group strives to fulfill its duty as a safety-conscious contractor by ensuring that construction projects are completed without accidents or disasters, and seeing that the five elements of the safe construction cycle are functioning smoothly.

- 1Training for new site visitors

- 2Implementation of work direction and KY

- 3Safety patrols

- 4Safety meetings

- 54S

Safety and health training

Based on the idea that the starting point of safety management is human resource development, the Toyota Tsusho Group conducts various safety and health educational programs for Group employees as well as suppliers in accordance with "Toyota Tsusho Group's Policies on Safety and Health."

We explain our policies on safety and health to employees and provides basic education on safety and health management. In addition to safety education (e-Learning) for all employees and "2S (Sunflower) Activities" in which all employees participate, various information is disseminated domestically and internationally via the Group intranet "ANZEN-NET," including activity policies, accident case studies and good practices, and safety education videos.

In fiscal year 2024, a total of 2,021 employees completed E-Learning courses on office safety. Additionally, individual training sessions were conducted as follows: 70 participants in new employee orientation, 52 in career employee onboarding, 176 in pre-departure training for overseas assignments, and 235 in the Practical Safety Workshop.

At domestic subsidiaries, we regularly provide legal training such as safety management training for new managers and training to become a foreman who directs and supervises workers at a work site to raise awareness of safety and health at work sites and prevent accidents. In fiscal year 2024, 66 employees participated in safety management training for new managers, 100 employees participated in training to become a foreman, and 352 employees participated in the Practical Safety Workshop.

The instructors who lead these health and safety programs understand conditions in the Toyota Tsusho Group and have been trained internally to respond to on-site circumstances. All instructors are qualified as "RST Trainers," which is an instructor qualification for safety and health education approved by the Ministry of Health, Labour and Welfare, and as "Specialized Instructors for All Toyota Work Supervisors," which is an instructor qualification for safety and health supervisor education in the Toyota Group.

We also provide information to the front lines of the workplace globally via safety and health-related personnel in Japan and overseas and the Group intranet to help prevent accidents, including safety awareness posters, 18 ironclad rules to prevent (STOP6*) accidents, and examples of past accidents.

Toyota Tsusho Delivery Safety and Health Cooperation Council general meeting

We provide safety and health education for suppliers, and regularly conduct various types of education for logistics delivery companies and construction workers at the Toyota Tsusho Construction: Safety and Health Cooperation Council and the Toyota Tsusho Delivery Safety and Health Cooperation Council as activities to ensure safety throughout the supply chain. In fiscal year 2024, 400 employees from 339 suppliers participated in top management training, in which lectures on safety and health were given by outside instructors, and 131 employees from suppliers participated in the Practical Safety Workshop.

At our overseas subsidiaries, safety staff at each company provide education to foremen at worksites. In fiscal year 2024, 37 overseas safety staff members also received training at the Practical Safety Workshop, and we are making efforts to improve safety and health education at local sites.

- *STOP6 accidents: Accidents caused by (1) moving machinery, (2) heavy objects, (3) contact with vehicles, (4) falls, (5) electric shock, and (6) high temperatures.

1. Practical safety workshop

In 2009, we established Practical Safety Workshop to develop human capital who can physically experience and learn the fear of hazards, enhance their sensitivity to danger, and carry out practical safety management. The workshop is an educational tool that utilizes VR technology and 60 different types of experiences, with a focus on "STOP6 accidents*" such as getting caught between or entangled in heavy objects, in which a single mistake can lead to a serious accident. The workshop is used not only by Toyota Tsusho Group employees globally, but also by a wide range of our business partners.

Over 11,871 people have used the workshop since its establishment, with 755 people using it in the fiscal year 2024.

- *STOP6 accidents: Accidents caused by (1) moving machinery, (2) heavy objects, (3) contact with vehicles, (4) falls, (5) electric shock, and (6) high temperatures.

2. Office safety workshops

As a trading company, much of Toyota Tsusho's work takes place in offices. For this reason, in the fiscal year ended March 31, 2017, we began conducting Office Safety Workshops and taking measures to raise awareness of safety with regard to office work. In the fiscal year 2023, approximately 100 employees, including those from Group companies, took the course. To date, over 1,000 people have attended, including Group company employees.

3. Fatal Accident Memorial

Every year, we hold a "Fatal Accident Memorial" on days when fatal accidents occur at Group companies to renew our commitment to eliminating accidents.

4. Disseminating Safety and Health Information

The Toyota Tsusho Group has been disseminating safety and health information on the Group intranet (ANZEN-NET) since 2009. We regularly make changes to the design and enhance the content. In 2016, we introduced the ASIST* accident reporting workflow system to promote the sharing of information among all concerned parties on a global basis.

In addition, we set up a "Zero Accident Corner" in our Nagoya Head Office to serve as a base for Toyota Tsusho's global safety activities.

- *ASIST: Abbreviation for Accurate Safety Information System for Toyotsu

5. Global Safety Awards

Each year, we recognize and commend Group companies for their record of continuous zero accidents and for their outstanding safety and health initiatives, thereby raising global safety awareness and sustaining motivation for activities.

Toyota Tsusho Group Employee Health Management Declaration

The Toyota Tsusho Group views employees as "human capital" and is working to continuously enhance their value in order to contribute to the development of local communities through business management and creation on the global stage. In October 2017, top management issued the Toyota Tsusho Group Health Declaration and since then has promoted health management. Toyota Tsusho Group will reinforce health management even further and convey internally and externally our ongoing commitment to promoting health management so that all employees can undertake business activities with an awareness of the Six Materialities.

Toyota Tsusho Group Employee Health Management Declaration

We of the Toyota Tsusho Group recognize that the physical and mental health of our employees is our most-important asset.

Thus, we welcome and respect the diversity of our employees and declare that we will strive to achieve work environments that provide peace of mind and opportunities for active participation by all. We also declare that we will unwaveringly adhere to our corporate principles and strive to become a value-creating entity by contributing to society through ever-better ways of doing business.

President & CEO Toshimitsu Imai

Three Guiding Principles of Health Management

The Toyota Tsusho Group believes that efforts to maintain and enhance good health contribute to higher employee engagement and organizational vitality, which in turn leads to higher corporate productivity. Based on this belief, we have positioned increasing health literacy as a top-priority issue to maintain and enhance independent health management for each employee, and conduct health management in accordance with the three policies described below.

Employee Health

In light of our global business activities, we will support our employees in acquiring awareness and knowledge of health issues so that they can pursue self-initiative in maintaining and improving their physical and mental wellbeing. And based on Diversity Equity & Inclusion (DE&I), we will support each employee to face various life stages and life events and work their own health challenges.

Improvement of Workplace Vitality

Based on Diversity Equity & Inclusion (DE&I) diverse human resources respect each other's differences and actively utilize them, we will create work environments that enables flexible work styles, and through mechanisms that encourage dialogue across organizational hierarchies, we will create an organization in which people who can think independently and act autonomously and independently continue to improve themselves, and in which these diverse human resources can pool their knowledge, co-create and collaborate to generate diverse ideas and synergies.

Social Contribution

We are committed to ensuring that each employee on the global stage is healthy in mind and body and highly engaged, and through wholesome business activities around the world, we will strive to endlessly contribute to the achieving of a prosperous society for an irreplaceable future.

Toyota Tsusho Health Management Initiatives

In March 2025, Toyota Tsusho was selected by Health and Productivity Management Excellent Corporation 2025 (White 500) from among the companies listed on the Tokyo Stock Exchange as a Health & Productivity Stock for its strategic effort in handling employee health from a management perspective.

Going forward, we will create workplaces in which each employee can work with vitality, leading to sustainable corporate growth.

Health management strategy

Toyota Tsusho promotes health management with the aim of securing both the quality and quantity of its human capital by enhancing each employee’s physical and mental health and by creating an environment where diverse human capital can work with vitality. Through these efforts, the company seeks to realize the well-being of all employees—being physically, mentally, and socially healthy.

As part of its health management strategy, Toyota Tsusho has clearly positioned the realization of well-being for its diverse human capital as a management policy that contributes to building a better future society, thereby embodying the vision of “People Company Toyotsu.” Medium-term targets have been established to guide these initiatives.

- Preventive measures for lifestyle-related diseases, mental disorders, infectious diseases, and cancer through implementation of measures and seminars, etc.

- Support for lifestyle improvement, reduction of psychological burden, and self-care through periodic medical examinations, various interviews, recommendations for detailed examinations, health consultation, and recommendations for health consultations on specified conditions by the Health and Welfare Union

Through these measures, we aim to improve the health literacy of our employees and support them in their efforts to maintain and promote their own health independently in any environment.

In addition, we are promoting more flexible and fulfilling work styles through systems related to working place and time and supporting the balance between work and life events, such as work-from-home and flextime systems, as well as office reforms and other initiatives. We are also implementing individual work engagement improvement, organizational revitalization, and DE&I. In doing this, we are working to create a system to utilize diverse human capital who will lead the evolution toward a better future.

The indicators and mid-term goals that we place particular emphasis on are as follows.

| index | Goals to be achieved by the end of fiscal year 2028 | remarks |

|---|---|---|

| KGI: Presenteeism | 32.0 | Measured by WHO-HPQ |

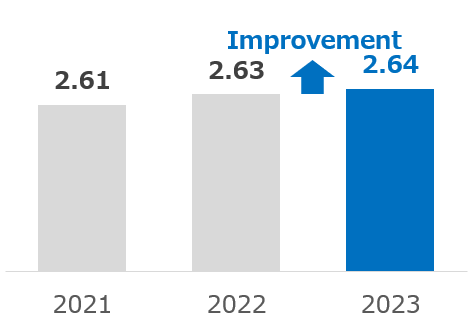

| KGI: Work Engagement | 2.7 | Measured using two items from the New Brief Job Stress Questionnaire related to work engagement |

| "KPI: Healthy Lifestyles Challenge 8 program" | 6.0 | Survey on the number of people who have achieved eight healthy habits |

| KPI: Health literacy | 19.0 | Measured using the CCHL scale |

| "KPI: Infectious disease prevention measures" | Continuing to have zero deaths while employed | - |

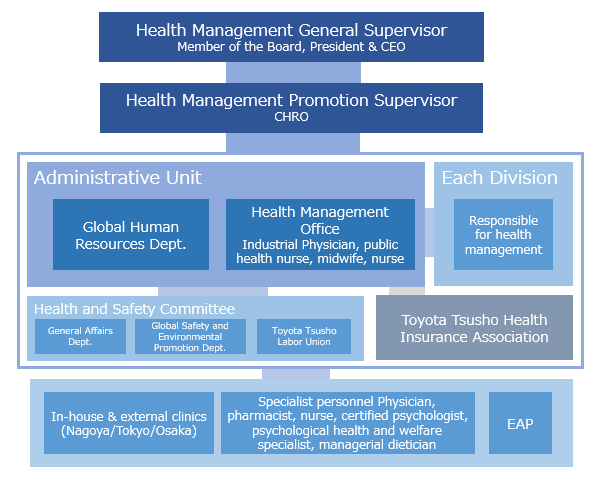

Health and productivity management promotion framework

The President and CEO is the person with highest responsibility, and the CHRO(Chief Human Resources Officer) is responsible for implementation. The Global Human Resources Department, Health Management Office, and health insurance association work together, hold regular meetings, and promote health management under the framework described below.

In addition, the "Health and Safety Committee" is chaired by the CHRO, who is responsible for health and safety. The committee meets monthly to discuss employee health and safety environments; it also reports to the Board of Directors on health and safety risks, depending on their severity. "The Health and Safety Committee" is also attended by a labor union officer, who represents all employee. Together, the committee members discuss how to promote employee health, and how to develop environments in which it is easy to work.

Results of health and productivity management initiatives

| FY2019 | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |||

|---|---|---|---|---|---|---|---|---|

| Consultation rate for periodic medical examinations | 100% | 100% | 100% | 100% | 100% | 100% | ||

| Consultation rate for detailed examinations | 94.9% | 97.1% | 95.6% | 87.9% | 85.9% | 90.9% | ||

| Consultation rate for cancer examinations | Gastric Cancer Risk Screening | 100% | 100% | 100% | 100% | 100% | 100% | |

| Colorectal Cancer Screening | 92.0% | 93.8% | 94.3% | 93.9% | 94.9% | 92.4% | ||

| Treatment rate*1 | Blood pressure | 90.2% | 90.3% | 95.1% | 98.2% | 93.6% | 95.2% | |

| Blood glucose level | 78.3% | 83.8% | 96.3% | 98.8% | 96.1% | 96.1% | ||

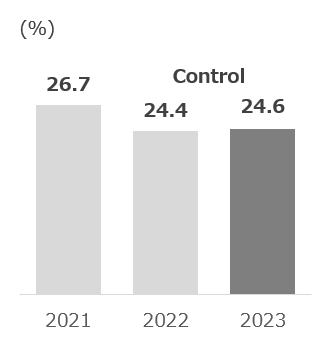

| Obesity rate | BMI more than 25 | All age groups | 23.4% | 23.6% | 22.9% | 24.1% | 22.9% | 24.2% |

| Under 40 years of age | 17.3% | 17.2% | 16.3% | 18.4% | 17.5% | 17.7% | ||

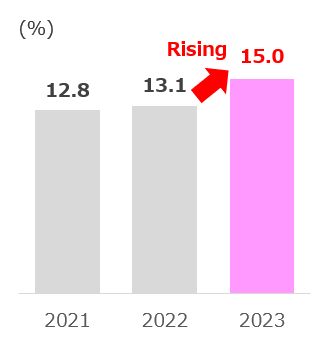

| Rate of smoking | Total | 20.8% | 18.0% | 17.5% | 17.0% | 16.8% | 16.3% | |

| Male | 29.9% | 25.8% | 25.2% | 23.8% | 23.8% | 23.1% | ||

| Female | 3.1% | 2.2% | 2.3% | 2.6% | 2.7% | 2.8% | ||

| Percentage of individuals who exercise regularly*2 | 46.2% | 45.4% | 47.0% | 53.2% | 55.1% | 57.2% | ||

| Percentage of individuals who are well-rested through sleep | 66.5% | 75.5% | 76.5% | 71.0% | 68.4% | 67.4% | ||

| Percentage of individuals who eat breakfast*3 | 74.9% | 76.0% | 74.9% | 73.1% | 73.1% | 74.6% | ||

| Stress check consultation rate | 88.4% | 97.2% | 98.5% | 99.0% | 98.0% | 98.1% | ||

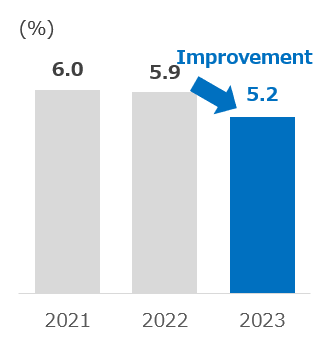

| Percentage of individuals with high stress | 8.4% | 5.3% | 7.9% | 9.0% | 8.6% | 8.9% | ||

| Long working hours | Occurrence rate of overtime work exceeding 50hours per month | 2.53% | 2.58% | 3.81% | 3.55% | 3.43% | 4.62% | |

| Interview rate of individuals engaging in interviews with an industrial physician*4 | 93.5% | 94.0% | 95.1% | 83.8% | 80.8% | 86.5% | ||

| Percentage of individuals taking annual paid leave | 65.8% | 52.8% | 57.0% | 66.1% | 62.5% | 64.9% | ||

| Infectious diseases seminar | cumulative number of persons | 2,600 | 2,600 | 2,629 | 3,424 | 3,590 | - | |

| Participation Rate | - | - | - | - | - | 81.7% | ||

| Absenteeism (percentage of individuals who were absent from work for more than 7 consecutive days due to non-occupational injury or illness)*5 | Physical | 0.21% | 0.12% | 0.19% | 0.25% | 0.38% | 0.23% | |

| Mental | 0.33% | 0.28% | 0.48% | 0.51% | 0.61% | 0.41% | ||

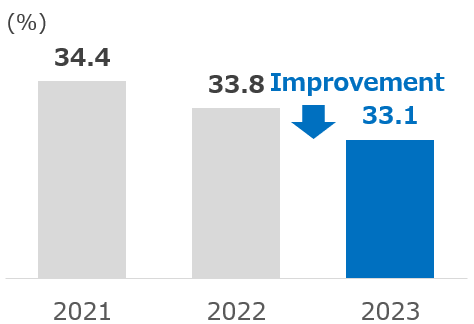

| Presenteeism (WHO-HPQ)*6 | - | 35.4 | 34.4 | 33.8 | 33.1 | 32.6 | ||

| Work engagement*6*7 | 2.61 | 2.65 | 2.61 | 2.63 | 2.64 | 2.66 | ||

| Implementation rate for health consultations on specified conditions | 39.8% | 32.2% | 51.8% | 62.8% | 67.5% | Under aggregation | ||

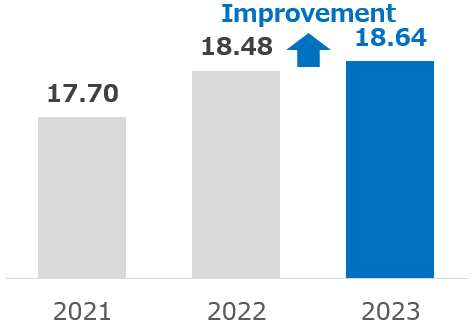

| Health Literacy*8 | - | - | 17.70 | 18.48 | 18.64 | 18.71 | ||

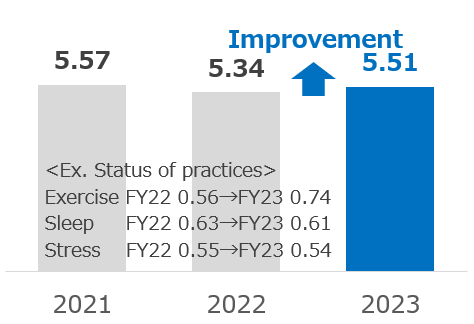

| Average number of Healthy Lifestyles Challenge 8 program items practiced | - | - | 5.57 | 5.34 | 5.51 | 5.50 | ||

- *1Percentage of individuals subject to treatment that received treatment

- *2Percentage of individuals who replied "yes" to "have you exercised to a light sweat for more than 30 minutes at a time, more than 2 days per week for at least one year?" or "do you walk or perform similar physical exercise in your daily life for more than 1 hour per day?"

- *3Percentage of individuals who replied "no" to "do you skip breakfast more than 3 times per week?"

- *4Implemented for 100% of individuals subject to legal interview criteria

- *5Number of applicable individuals in FY2024: 3,603 (Number of employees enrolled as of March 1 of the subject fiscal year)

- *6Number of respondents in FY2024: :2,975; response rate: 98.1%

- *7New Brief Occupational Stress Questionnaire Measures two items related to work engagement (minimum score of 1 to maximum score of 4, with higher scores indicating better)

- *8Measured using the Communicative and Critical Health Literacy (CCHL) scale

General Comments: As the importance of obesity countermeasures increases among young people as well as middle-aged people, we have been providing obesity guidance using the "Lifestyle-related Disease Risk Report," which analyzes health checkup results using big data and predictive models, in addition to strengthening specific health guidance in collaboration with health insurance societies. These measures as a high-risk approach are expected to halt the increase in the ratio of obese persons and lead to prevention of lifestyle-related diseases in the future. In addition, as a population approach, we introduced Health Challenge 8 to raise the health literacy of all employees. Presenteeism is also improving, as the ratio of employees who are in the habit of exercising has been increasing. On the other hand, the high ratio of high-stress employees due to accumulated psychological stress has become an issue in recent years. We will enhance work engagement by introducing "Nomad Day," a day when employees have complete freedom in terms of floor space and seating, to stimulate inter-organizational communication, and by enhancing line care through practical mental health training for managers.

Health promotion measures

1. Employee Health

We have introduced the Healthy Lifestyles Challenge 8 programs promoted by the Toyota Group. This program encourages improvements in eight areas (appropriate weight, exercise, drinking, smoking, breakfast, snacking, sleep and stress).

Toyota Tsusho's Healthy Lifestyles Challenge 8 Programs

Of the eight healthy practices, one point is awarded for each that is practiced for a perfect score of eight points. We calculate the average employee score and plan and implement measures for each of these healthy practices using the Healthy Lifestyles Challenge 8 KPI as an indicator for evaluating overall health management. In addition to the "Healthy Lifestyle Challenge 8," each employee chooses one issue from the eight health habits and makes a "My Health Declaration" and works on continuous improvement.

In the questionnaire at the end of the fiscal year 2023, only about 49.1% of the employees were able to achieve their "My Health Declaration." To encourage employees to put healthy habits into practice, Toyota Tsusho raises awareness by hosting events in employee cafeterias that feature daily menus related to the Healthy Lifestyle Challenge 8 items. In addition, the company promotes greater health consciousness by publishing a Health Column and an employee-participation feature titled “My Health Declaration” in its in-house newsletter, issued quarterly.

In the questionnaire at the end of the fiscal year 2024, 90% of employees were aware of Healthy Lifestyles Challenge 8 activities, and nearly 60% of them answered that they are taking lifestyle actions with this in mind. 51.6% was able to achieve "My Health Declaration", which is gradually increasing. We will continue to widely disseminate information about each seminar and devise measures and methods to make it easier to participate, in order to increase the participation rate and promote behavioral change toward the practice of healthy habits.

Figures for Health Management Initiatives through Healthy Lifestyles Challenge 8 Programs

Since the introduction of the Healthy Lifestyles Challenge 8 items, Toyota Tsusho has been organizing seminars and interactive events related to the eight healthy habits, providing opportunities to enhance health literacy and encourage behavioral practice. We began measuring health literacy in the fiscal year 2021, and in fiscal year 2024, it was 18.71, 0.07 points higher than the previous year. The presenteeism loss ratio was 32.6, a 0.5 point improvement from the previous year.

Through the Healthy Lifestyles Challenge 8 items, we have been able to gradually demonstrate results in laying the foundation for employees to independently maintain and promote their health and improve their performance.

The average number of Healthy Lifestyles Challenge 8 items practiced was 5.50, remaining almost unchanged from the previous year. In particular, efforts related to exercise have been strengthened through seminars and other initiatives to deepen employees’ understanding of its importance and benefits, leading to gradual progress in encouraging voluntary behavioral habits. On the other hand, the average practice level for sleep declined compared with the previous year. As employee interest in sleep is high, Toyota Tsusho designated July 2024 as Wellness Month and held a sleep seminar, which was attended by 399 employees. Through such initiatives, the company will continue to provide information aimed at improving sleep quality, while also promoting effective use of the flextime system and work interval system to encourage balanced working styles and ensure sufficient sleep.

Going forward, we will promote behavioral change among employees by continuing to encourage healthy habits through each measure of the Healthy Lifestyles Challenge 8 Program items. We will also support each employee in independently maintaining and promoting their health by maintaining and improving the number of Healthy Lifestyles Challenge 8 items practiced.

(HbA1c)

(LDL cholesterol)

*Percentage of respondents who judged that a close examination and lifestyle modification or treatment is required, with reference to the standard by Japan Society of Ningen Dock and Preventive Medical Care

In fiscal year 2024, the proportion of employees with findings related to blood pressure and blood glucose showed a slight increase, while those with lipid-related findings decreased. Although these results were partly influenced by the rise in average age, certain progress has been made—particularly among younger employees—in preventing lifestyle-related diseases. Going forward, Toyota Tsusho will continue to support employees in maintaining healthy lifestyle habits through various initiatives and events, while also fostering an organizational culture and environment where diverse human capital can work with vitality and thrive.

Cooperation with Toyota Tsusho Health and Welfare Union

In collaboration with the health insurance association, Toyota Tsusho is working to improve the rate of health guidance for those 40 years of age and older. For eligible employees, the company utilizes individual medical examination results along with big-data–based simulation analyses to predict future outcomes, conducting face-to-face consultations in addition to these tools. As a result, the implementation rate of health consultations on specified conditions reached 67.5% in fiscal year 2023, a significant improvement compared with 39.8% in fiscal year 2019, demonstrating major progress in secondary prevention efforts aimed at preventing lifestyle-related diseases. We will continue to provide health consultation in order to improve guidance rates and reduce the number eligible persons.

Obesity Countermeasures

To prevent the occurrence of obesity-related lifestyle-related diseases, cerebrovascular diseases, and ischemic heart disease, the company places emphasis on early intervention for younger generations. Health guidance was provided to employees under the age of 40 who were at risk of metabolic syndrome, using the Lifestyle-related Disease Risk Report, which analyzes individual health checkup results through big data and predictive models. As a result, 83% of the target group reported being very satisfied or satisfied with the health guidance.

We continue to hold seminars by dietitians on breakfast and snacks for employees who tend to eat out and drink alcohol frequently and have disordered eating habits, provide information via video clips, and implement meal planning initiatives in collaboration with other companies. We will continue our efforts to reduce the number of obese employees in the future.

Exercise Practice Measures

Through the planning of online seminars and physical fitness testing sessions, as well as regular information dissemination, we aim to deepen employees' understanding of the importance and benefits of exercise and increase the number of employees who voluntarily and continuously engage in physical activity.

In collaboration with the health insurance association, Toyota Tsusho regularly holds charity walking events that donate school meals to children in developing countries based on the total number of steps achieved. As an incentive to encourage exercise, the company has also launched an initiative that awards points according to participation in seminars and individual exercise achievements.

Together with the Healthy Lifestyles Challenge 8 items, these initiatives have gradually produced positive results, leading to an overall increase in the percentage of employees with regular exercise habits. Analysis of step counts and exercise habits showed that participants in the events increased their average number of steps by 19% compared with normal periods, and the results also indicated contributions to improved stress check scores and reduced presenteeism. We will continue this activity to improve employee wellbeing through the synergy effect of exercise habits and social contribution.

Antismoking measures

To strengthen anti-smoking measures, Toyota Tsusho has implemented a completely smoke-free workplace policy and introduced a subsidy program for smoking-cessation outpatient treatment to support employees who are attempting to quit smoking. For employees who have not yet been able to take the first step toward quitting, the company provides regular informational support through column distributions and pamphlets, as well as individual consultations with public health nurses to assist self-directed cessation efforts.

As an incentive to maintain a smoke-free lifestyle, Toyota Tsusho, in collaboration with the health insurance association, offers points to non-smokers through a health-promotion app. A company-wide survey revealed that about 70% of employees who successfully quit smoking stated that these initiatives contributed to their behavioral change and encouraged them to take voluntary action.

In fiscal year 2024, the smoking rate among male employees was 23.1%, and the overall rate was 16.3%. We will continue to support further cessation efforts with the goal of reducing the overall smoking rate to less than 15% by the end of fiscal year 2027.

Cancer countermeasures

In light of the increase in cancer cases associated with population aging, Toyota Tsusho continues to provide accurate information on cancer prevention through seminars conducted by occupational physicians and in collaboration with external organizations. In cooperation with the health insurance association, the company also encourages employees to undergo cancer screenings through comprehensive medical examinations. Furthermore, to facilitate early detection of cancer risk and prevent onset through timely treatment, Toyota Tsusho conducts gastric cancer risk screenings (ABC tests) for all employees during regular medical examinations. Employees found to be infected with Helicobacter pylori have successfully completed eradication treatment, leading to early detection and prevention of cancer development. In addition, the company has introduced colorectal cancer screenings (fecal occult blood tests) for all employees aged 40 and over, as well as a new, science-based cancer screening subsidy program.

We will continue to provide support for early detection of cancer risk and prevention of the onset of cancer through treatment. In addition, we will develop and operate a work environment that allows employees suffering from cancer to balance treatment and work with peace of mind, including a leave system that can be used for hospital visits and a work system that enables flexible work styles.

Mental health

As mental health measures, we focus on stress caused by environmental changes such as joining a company or working overseas, and mental health deterioration caused by jet lag after an overseas business trip. As part of our efforts to prevent mental health problems, we offer interviews with industrial physicians and public health nurses for new graduates in their first and second year of employment and career employees, and provide opportunities for them to learn about self-care and in-house mental health support. As part of our measures to prevent overwork, we have established our own standards that combine overseas business trip history and overtime work to specially target employees for interviews with industrial physicians. Stress checks are also conducted on employees who work overseas, and employees with high levels of stress, whether in Japan or overseas, are invited to meet with industrial physicians and receive the necessary support. As a line care measure, we hold practical line care training for managers based on the results of organizational diagnosis. To encourage self-care, we provide mental health management training via e-learning for all employees. In addition, we will continue to support the mental health of our employees by providing information and resources related to mental health, including the establishment of an external consultation service that not only employees but also their families in Japan and overseas can feel free to use.

Every October, Toyota Tsusho designates a company-wide Compliance Awareness Month to strengthen awareness initiatives. During this period, the company conducts an e-learning program titled “Say NO to Harassment Together” to promote the elimination of harassment, and in fiscal year 2025, it also held “Training for Harassment Consultation Desk Representatives.”

Health Support for Female Employees

As part of its efforts to support female employees, Toyota Tsusho renamed its menstrual leave as “Ladies’ Leave” and expanded its scope to include infertility treatment. In addition, around International Women’s Day each March, the company conducts health seminars focusing on women’s unique health issues and life stage changes. Working in cooperation with the health insurance association, Toyota Tsusho also provides subsidies for medical examinations specific to women’s health, such as gynecological checkups for breast and cervical cancer and bone density tests.

In developing the next generation of female leaders, the company provides both internal and external mentoring opportunities to raise career awareness, broaden perspectives, and support problem-solving, thereby fostering an environment where women can thrive with confidence and vitality.

Starting in 2024, Toyota Tsusho introduced an e-learning program aimed at creating a more open atmosphere for discussing women’s specific health issues and developing a culture of mutual understanding and respect between men and women. This initiative also encourages dialogue across hierarchical levels as part of efforts to build an inclusive workplace.

From March to August 2024, three themes were defined and e-learning was conducted to create an atmosphere in which it is easy to discuss women's specific health issues while staying close to them, and to create opportunities for both men and women to deepen mutual understanding and encourage dialogue across hierarchical boundaries as part of creating a climate of mutual respect and recognition of each other's differences. The e-learning program was implemented. We have made steady efforts to promote the provision of the e-learning program through videos over a certain period of time and to encourage participants to take the course. The openness of the content and the high participation rate have provided an opportunity to create a climate of mutual recognition and respect.

| Training name | Participation rate in fiscal year 2024 |

|---|---|

| Men's and Women's Health | 83.2% |

| Men's Health | 83.1% |

| Managers Edition (for managers) | 81.2% |

2. Improvement of Workplace Vitality

Ikiwaku Activities

Conducted at a small department or group level, "Ikiwaku Activities" (activities aimed at creating a motivated and productive organization) consist of each member thinking of topics to focus on to achieve growth for the organization and then all members working to implement the decided actions. These activities encourage consensus building through an exchange of opinions between all members and an acceptance of the individual values of each member. They aim to foster an awareness and culture of autonomous and voluntary action. These activities lead to a range of initiatives, including efforts to implement new work styles and study groups to discuss new businesses, which can improve the dynamism in workplaces. We are also expanding these activities to affiliate companies.

In addition to the above activites, we visualize the state of the organization through engagement surveys and hold workshops and lectures to encourage enthusiasm and engagement for each employee.

Work Style Reform

While promoting flexible work styles through the introduction of work-from-home and flextime systems, Toyota Tsusho is also implementing various initiatives such as office reforms to revitalize communication among employees, which can become diluted under flexible arrangements. These efforts aim to foster and pass down Toyota Tsusho’s unique corporate culture by encouraging cross-organizational dialogue, casual information exchange, and mutual learning that lead to the creation of new value.

Every Wednesday is designated as “Nomad Day,” during which employees are encouraged to work in a hot-desking style across office floors. After working hours, the cafeteria space is opened for “Nomad Night,” an event designed to promote vertical, horizontal, and diagonal communication across different departments and levels.

Time management

The company also promotes a well-balanced working style through measures such as turning off all office lights at 8:00 p.m. to encourage early departure, gradually lowering the upper limit of the special provisions under the Article 36 Agreement, and prohibiting business communication during late-night hours (10:00 p.m. to 5:00 a.m.) starting in fiscal year 2025. These efforts have achieved certain results in reducing long working hours and decreasing overtime.

In addition, Toyota Tsusho has introduced a work interval system and promotes the use of paid leave through the Monthly Paid Leave Campaign, thereby helping employees maintain their health, reduce mental and physical fatigue, and improve productivity.

3. Social Contribution

We are taking measures against infectious diseases and providing medical support for personnel assigned overseas, and their families, so that they can work with peace of mind in their various overseas territories and can contribute to society through business.

Measures to control infectious diseases

Many of our employees take business trips or are assigned to work overseas. To protect their health, we launched infectious disease seminars in the fiscal year 2017 for such employees., with a total of 3,590 participants by fiscal year 2023. In fiscal year 2024, the program content was revised, and an e-learning version of the seminar was implemented, attended by 3,026 employees, including those working overseas.

During pre-departure medical consultations with occupational physicians, employees are required to submit their vaccination history, receive vaccination advice, and have their records stored in medical charts, thereby ensuring proper management of travelers’ vaccine histories, and actively promote vaccinations against infectious diseases for not only persons assigned overseas but for family members accompanying them as well as business travelers.

Using information provided by the Ministry of Foreign Affairs, International SOS, Control Risk, and other sources, we communicate the latest information regarding infectious disease outbreaks in Japan and overseas to employees on business trips and employees assigned overseas. We also provide support for our employees' health management. This support includes providing vaccinations that may be required at their destinations, informing overseas business travelers of specialized medical facilities in the vicinity of domestic sites in case they have concerns about symptoms such as fever after returning home, and promoting medical examinations.

| Name | Training Contents | Number of participants in fiscal year 2024 | 2024 Annual Course Enrollment Rate |

|---|---|---|---|

| Infectious Diseases Prevention Seminar | Education on the risks of malaria and other infectious diseases and health care while working/traveling abroad | 3,026people | 81.7% |

*Excluding spouse

Medical Support for Overseas Workers

Prior to overseas assignments, industrial physicians and public health nurses meet with all employees scheduled for overseas assignments to determine whether or not they can travel and to confirm their physical and mental condition prior to the trip. During overseas assignments, Toyota Tsusho requires employees to undergo annual medical examinations. All results are reviewed by occupational physicians, who provide individualized guidance and alerts based on specific medical risks in each country or region. Employees identified as high-risk in terms of health management or working under high-stress conditions receive continuous support, including regular online consultations.

While working overseas, annual medical examinations are mandatory, with all results reviewed by an industrial physician, and reminders are sent to each employee, taking into consideration the medical risks in each country and region. For employees at high risk in terms of health management and those working in high-stress environments, we provide extensive follow-up, including periodic online interviews.

In addition, industrial physicians and overseas staff in charge of health management regularly visit the workplace to check the actual working environment, sanitary environment, and medical system. In addition to the Health Management Office and the external EAP as a contact point for casual consultation, we also provide medical support for employees working overseas and their families in cooperation with overseas administrative base staff and local medical assistant companies.

For example, in response to the serious social issue of HIV/AIDS in Sub-Saharan Africa, Toyota Tsusho provides prevention, testing, and treatment programs for employees and their families working in the region against diseases such as HIV and malaria. CFAO, which operates across all 54 countries in Africa, carries out initiatives under the banner of “Health by CFAO,” addressing chronic diseases with high prevalence in developing countries—such as HIV, diabetes, malaria, hypertension, and tuberculosis—through awareness programs, prevention efforts, testing, and guidance.

Contributing to local communities

The Toyota Tsusho Group believes that contributing to the local communities in which it operates is an essential part of achieving sustainable development together.

As a company conducting business in regions with high risks of the world’s three major infectious diseases, Toyota Tsusho engages in a variety of preventive activities, including those targeting local residents, such as the following:

- Educating people about and working to prevent contraction of AIDS, tuberculosis, and malaria; providing information regarding prevention and treatments, such as the free distribution of contraceptives

- Providing support to medical organizations, and to children orphaned by HIV