Toyota Tsusho, Yano Research Institute and ISONO Continue Vehicle Plastics Recycling Demonstration Project for Promoting the Use of Recycled Plastics

- (former)Chemicals & Electronics

2018-09-03

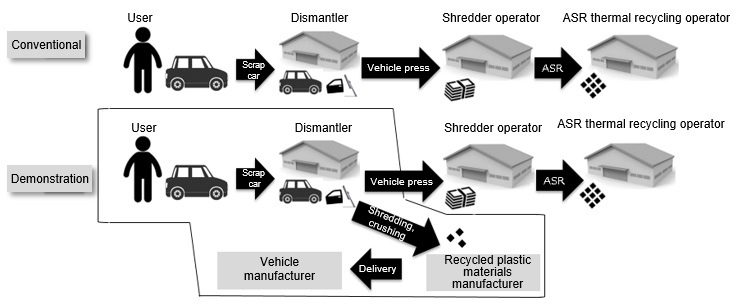

Toyota Tsusho Corporation (Toyota Tsusho), Yano Research Institute Ltd. (Yano Research Institute) and ISONO Co., Ltd. (ISONO) were commissioned in 2017 to undertake a demonstration project investigating the possibility of Car to Car recycling1 of plastic materials used in vehicles, and commenced the second year of the demonstration project at the end of August 2018. Based on results from the previous fiscal year, the project aims to recycle plastic parts and materials included in used vehicles by methods that have as low an environmental impact as possible, and to utilize resources effectively in a sustainable form.

1. Background and Purpose

As a demonstration project to contribute to the “Promotion of advanced vehicle recycling system and reduction of the recycling fees paid by vehicle users” proposed by councils and others involved in vehicle recycling, this project was adopted in the “Fiscal 2017 Projects for Promoting Researches, Studies, Demonstrations and Other Activities to Progress to More Advanced Recycling system and other improvements” of the Japan Foundation for Advanced Auto Recycling.

Since the end of 2017, recycling of plastics has become more important for reasons including the ban implemented by China on importing of solid wastes including plastic wastes and the problem of marine plastic pollution.

Currently, in addition to parts and materials that cannot be reused or used in materials recycling2, many of the plastics used in vehicles are subject to thermal recycling4 as part of ASR3, and Car to Car recycling has not progressed. Reasons given include the high costs of removal, the deterioration of plastics, and securing amounts of materials. As approximately one-third of ASR is plastics, materials recycling of plastic parts will reduce ASR, and may also lead to reductions in vehicle recycling fees paid by users.

2. Results of the FY2017 Demonstration

In FY2017, seven exterior parts were chosen by automotive manufacturers as candidates for the recovery of plastics. Approximately 20 kg of each part per automotive manufacturer were collected by six cooperating dismantlers in the Chubu area, and the degree of deterioration and methods of parts dismantling and recovery were tested. Based on the results, three of the seven parts were made subject parts in FY2018, and it was decided to add new parts. Ensuring the profitability of recovery work by shortening the dismantling period was also included as an issue.

3. Details of the FY2018 Demonstration

This fiscal year, in addition to continuing the recovery of parts from the previous fiscal year, four internal parts have been added as subjects for recovery. Also, the scale of recovery has been expanded to 300 kg per part, and the issues of man-hours pertaining to the removal of parts and foreign body removal and when dismantling, and expanding the scale of testing of efficient dismantling methods, will be included. Accordingly, it is planned that, with the cooperation of a total of 12 dismantling companies, including newly added TCR members5 in the Kanto area, approximately 2,400 used vehicles will be dismantled and parts recovered from them. In addition, in terms of quality verification, the degree of degradation of plastic parts that have been removed will be tested by ISONO, and a summary of data acquired and issues to be resolved will be performed by Yano Research Institute. This fiscal year, it is also planned to address the development of recycled plastics that are competitive in terms of quality and price.

List of Dismantling Companies

| Chubu Area | Kanto Area |

|---|---|

|

- Kobayashi Shoten Co., Ltd.

- Johoku Jidosha Kogyo Co., Ltd. - New Iwata Co., Ltd. - Marudai Sangyo Co.,Ltd. - Morita Cars. Co., Ltd. - Yamauchi Shoten Co., Ltd. |

- Ibaraki Auto Parts Center Co., Ltd.

- Urawa Jidosha Kaitai Co., Ltd. - Eco-R Co., Ltd. - Kaizuka Shokai,Ltd. - Keiyo Auto Trading Inc. - Showa Metal Co.,Ltd. |

- 1Car to Car recycling

Resources recovered from used vehicles are used again as raw materials for vehicle manufacturing.

- 2Materials recycling

Waste plastics are used as raw materials for plastic products.

- 3ASR

(Automotive Shredder Residue)Currently approximately 20% of parts and materials comprised in used vehicles become ASR.

- 4Thermal recycling

Resources that cannot be recycled into raw materials are used as fuel sources.

- 5TCR members

TCR is an organization of vehicle dismantlers which aims to contribute society through comprehensive operations for recycling used vehicles and has an office within the Toyota Tsusho Group.

The information in this release is current as of the date of announcement.

Please note that information may change after the date of announcement. Thank you in advance for your understanding.